The coarseness of a bandsaw’s blade is rated in – The coarseness of a bandsaw’s blade is a crucial factor that affects its cutting performance and the quality of the cut. Understanding the different coarseness levels and how they impact the blade’s functionality is essential for selecting the right blade for your specific needs.

This comprehensive guide delves into the various aspects of bandsaw blade coarseness, providing valuable insights into its measurement, impact on performance, and maintenance techniques. Whether you’re a seasoned woodworker or just starting out, this guide will empower you with the knowledge to make informed decisions and achieve optimal results with your bandsaw.

Introduction

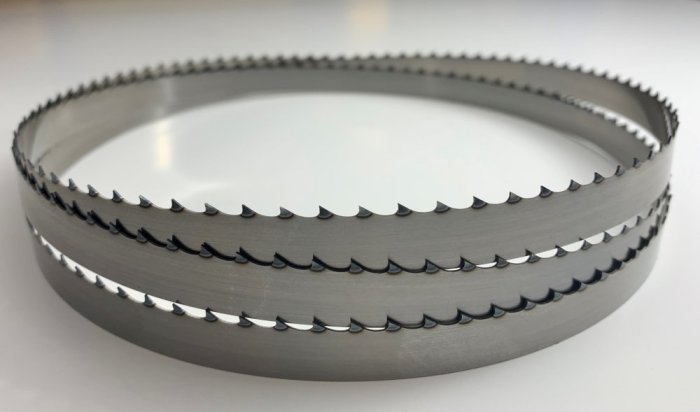

Understanding the coarseness of a bandsaw blade is crucial for achieving optimal cutting performance and finish quality. The coarseness, also known as teeth per inch (TPI), refers to the number of teeth present along a one-inch section of the blade.

This factor significantly influences the blade’s cutting efficiency, smoothness of cut, and suitability for different materials.

Various factors can affect the coarseness of a bandsaw blade, including the intended purpose, material being cut, and desired cut quality. Blades with higher TPI are generally used for finer cuts and produce a smoother finish, while blades with lower TPI are more suitable for faster cutting and thicker materials.

Measuring Blade Coarseness

Measuring the coarseness of a bandsaw blade can be done using several methods:

- Visual Inspection:Counting the teeth along a one-inch section of the blade.

- TPI Gauge:A specialized tool that measures the distance between teeth.

- Blade Manufacturer’s Specifications:The TPI is typically indicated on the blade’s packaging or documentation.

Common units of measurement for TPI include teeth per inch (TPI) and teeth per centimeter (TPC). TPI is the more widely used unit, especially in North America.

Impact of Blade Coarseness on Performance, The coarseness of a bandsaw’s blade is rated in

The coarseness of a bandsaw blade has a significant impact on its performance:

- Cutting Efficiency:Blades with higher TPI cut more slowly but produce a smoother finish, while blades with lower TPI cut faster but produce a rougher finish.

- Finish Quality:Higher TPI blades create a cleaner and more precise cut, ideal for detailed work and finer materials. Lower TPI blades are better suited for rough cuts and thicker materials.

- Material Compatibility:Different materials require different TPI ranges. For example, wood typically requires higher TPI blades (10-18 TPI), while metal requires lower TPI blades (4-8 TPI).

Selecting the Right Blade Coarseness

Selecting the appropriate blade coarseness depends on several factors:

- Material:The type of material being cut determines the recommended TPI range.

- Thickness:Thicker materials require lower TPI blades.

- Desired Cut Quality:Higher TPI blades produce finer cuts, while lower TPI blades produce rougher cuts.

The following table provides a general guide to blade coarseness levels and their recommended applications:

| TPI | Application |

|---|---|

| 4-8 | Thick metal, pipes |

| 10-14 | Hardwood, plywood |

| 15-18 | Softwood, plastics |

| 19-24 | Fine woodworking, curves |

Maintaining Blade Coarseness

Maintaining the coarseness of a bandsaw blade is essential for consistent performance:

- Sharpening:Regular sharpening helps maintain the blade’s cutting efficiency and prevents premature wear.

- Storage:Store blades in a dry, cool place to prevent rust and maintain their sharpness.

- Avoid Overheating:Excessive heat during cutting can damage the blade’s temper and reduce its lifespan.

User Queries: The Coarseness Of A Bandsaw’s Blade Is Rated In

What factors affect the coarseness of a bandsaw blade?

The coarseness of a bandsaw blade is primarily determined by the number of teeth per inch (TPI). Blades with higher TPI have more teeth and are considered finer, while blades with lower TPI have fewer teeth and are considered coarser.

How does blade coarseness impact cutting performance?

Blade coarseness affects the cutting efficiency and the quality of the cut. Finer blades with higher TPI produce smoother cuts with less tear-out, while coarser blades with lower TPI are more aggressive and can handle thicker materials.

How can I maintain the coarseness of a bandsaw blade?

Proper blade sharpening and storage techniques are crucial for maintaining the coarseness of a bandsaw blade. Sharpening the blade regularly will ensure optimal cutting performance, while storing the blade in a dry and protected environment will prevent rust and damage.